June 14, 2023 – “We’re not only producing things of value for our local partners but vibrant parts of the workforce.” That’s Dr. Mark Buckner sharing the exciting new opportunities coming out of Oak Ridge High School (ORHS)—Wildcat Manufacturing. It’s a full-circle story of training, jobs, and partnerships that IACMI—The Composites Institute has helped facilitate. Mark adds, “This project with IACMI is the kind of project we’re looking for.”

What is Wildcat Manufacturing?

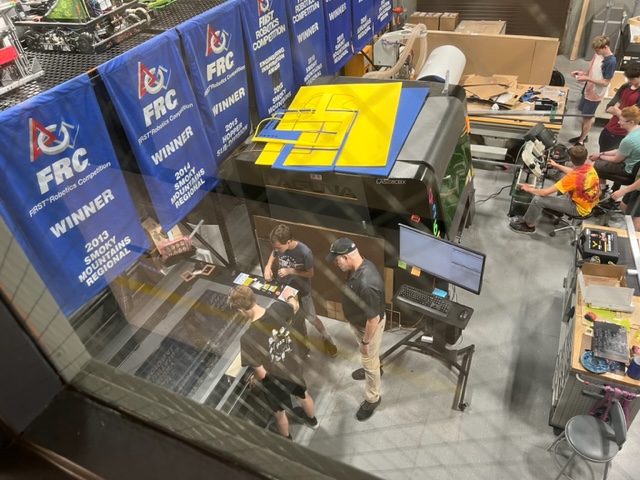

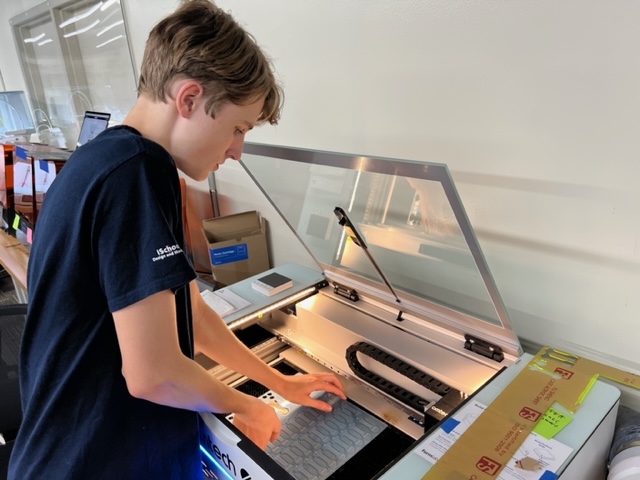

Wildcat Manufacturing is a student-run enterprise that focuses on interacting with customers to generate design and manufacturing innovations. Thanks to a $1.24 million grant, ORHS in Tennessee has an impressive machine shop including 8 commercial 3D printers, 5 resin printers, laser cutters, a water jet, lathes, a nylon powder bed printer, and a 5-axis CNC machine. That grant was designed to be a sustainable investment, so that the school could become a practical machine shop for the community. Students learn hands-on skills in classes, they meet with local businesses to discuss their needs, and then they form a plan. They design, iterate, prototype, iterate, machine, iterate, and deliver. This is way more than button pushing.

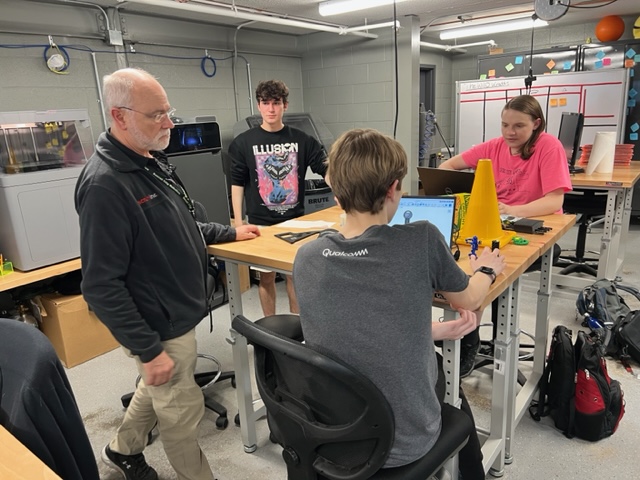

“The best part of this for me is the iteration process,” says Devin Slattery, a 16-year-old who’s first paying job is at Wildcat Manufacturing. “I like creating a design in CAD (computer-aided design), but the first idea is rarely the last one. Iteration creates the best product.” Mark adds, “The technology will change. The people part, the problem-solving part, bringing creative solutions is always going to be needed.”

How did IACMI get involved with Wildcat Manufacturing?

In June, IACMI will host 250+ composite and advanced manufacturing experts in Knoxville for its Summer 2023 Members Meeting. As we honed in on Knoxville’s nickname, the Maker City, we searched for local artists who could make a special memento for our members to take home as keepsakes. Then it hit us! Wildcat Manufacturing could make exactly what we wanted. We knew the kids who were active in the shop, because they had all gone through training that IACMI helps manage: America’s Cutting Edge (ACE). Through Roane State Community College, they are one of the facilities that host ACE bootcamps for CNC training. They prove high school is definitely not too young to start learning about machining.

Mark feels ACE provides a great introduction to equipment that can otherwise be intimidating. He says, “Through ACE, they see the world of digital design and manufacturing as a system. And at the end of it, they should think I can do this, I can really do this!”

That’s why we had full confidence that teenagers could handle delivering 300 custom pieces of SWAG (Stuff We All Get). They’re hired! For us, this project is much more than a bunch of trinkets. It’s an example of revitalizing U.S. manufacturing.

Customizing an Icon

Over 40 years ago, the World’s Fair in Knoxville created a new icon for our city, the golden Sunsphere. It’s in every skyline and provides spectacular 360-degree views with a scenic backdrop of the Great Smoky Mountains. Plus, it’s right beside our event venue, the Marriott Knoxville Downtown. Our SWAG had to feature the colorful Sunsphere, but we needed to make the connection with composites, which are often black. And don’t forget this is a branding tool for IACMI.

In our first brainstorming session, Devin comes up with the idea of putting our logo inside the Sunsphere ball. Senior Vigo De Almeida suggests we make two parts: the Sunsphere which could be etched in colorful acrylic and a carbon fiber base with 3D printing to make it stand up. Then sophomore Silas Rowden chimes in, “Something to sit on your desk is cool, but what if it could double as a keychain?” Now we’re talking! Once we realize we could use composite filament from IACMI member Vartega, we have a plan.

Plans Change

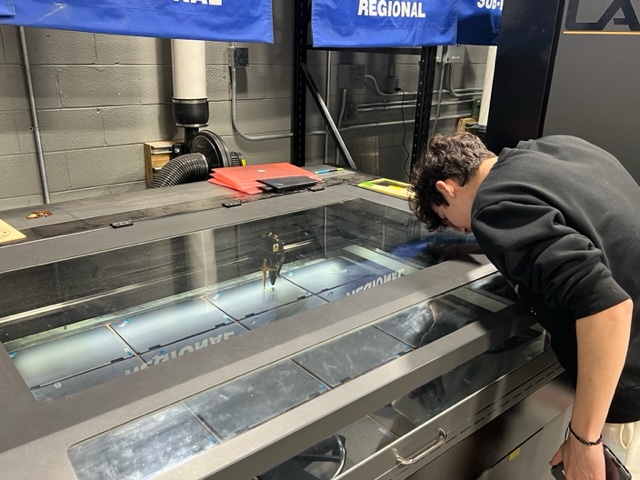

But what ever goes as planned? The first order of filament is lost in shipping. When the second arrives, they realize they need a different nozzle to print this material. We had planned to use multiple 3D printers; now we have to rely on one. Then the high-speed laser cutter that’s as reliable as Old Faithful…breaks. They have another one, but it’s smaller and slower. All these problems present a mounting challenge not of capability but of time. Could they deliver? They have to find a way.

So, they do what any good machine shop does: they run first, second, and third shifts. Once they get a reliable prototype (and yes, that is a bit of a struggle, too), the 3D printer begins running 24/7. They estimate it will take 84 hours of print time for the bases and 18 hours on the laser cutter. The students power through as a team and expect to finish in the next few days, just in time!

We hope our members and visitors to Knoxville look at the little memento from the IACMI Members Meeting and have a new appreciation for what goes into making most anything we see on store shelves. It’s not just about stuff. American manufacturing will rise because of creativity, perseverance, and grit.

Changing Lives

After 32 years at Oak Ridge National Laboratory, Mark retired and became a teacher, because he is looking to leave a legacy. It’s a model he’s calling iSchool that can be duplicated across the country. Beyond the classes Mark and his colleagues teach here, they’ve also equipped a trailer full of technology for a maker lab that can be driven to elementary and middle schools across rural Tennessee. “I’m trying to create a viable business model where this learning ecosystem can live long beyond myself. We’re not going to the community asking for hand-outs, but working with this technology costs money. We’re only going to be successful through partnerships. That’s how we keep this thing moving forward beyond our immediate region. That’s how we thrive and change lives.”

With that, he gets choked up when he remembers a note from a current student because this program has changed the trajectory of what she thought was possible.

Dear Dr. B,

Thank you for being an awesome teacher and robotics mentor! Your iSchool class gave me a chance to learn things I’ve never learned in any of my other classes, and I’m so glad I joined robotics and Wildcat Manufacturing. It’s changing my life!

Thank you,

Imelia