Oak Ridge National Laboratory (ORNL), which has done intensive research into carbon fiber, has developed a surface preparation method to improve joining the composites with aluminum. The ramifications are potentially far-reaching for high-volume industrial applications.

ORNL came into the national spotlight when it helped make possible Local Motors’ first 3D-printed car. More recently, it’s developed a fast, cheap, industrial-grade, structural carbon fiber production method it’s sharing with US manufacturers via a licensing program.

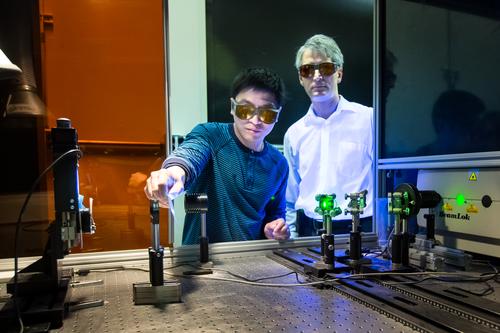

Oak Ridge National Laboratory’s Jian Chen (left) and Adrian Sabau work with a laser to prepare the surfaces of carbon fiber composites and aluminum before joining. This new surface preparation technique creates superior bonds that can absorb 200% more energy than bonds made with conventional preparation techniques.

(Source: Oak Ridge National Laboratory)

Read the full article and view the video on DesignNews.com