Written by: Stephan Biller, Amrine Distinguished Professor in Industrial Engineering and the Purdue Business School at Purdue University

Our current political divisiveness is grounded in the separation of haves and have-nots. It stinks to be on the have-not side, and it can happen to anybody. Manufacturing helps to move people to the have side. So, how can we bring offshored manufacturing back to the United States, and how can we ensure that current manufacturing stays in our country?

The answer is smart manufacturing, fueled by widespread digital transformation across the entirety of the production sector. My colleague Byron Pipes recently talked about how democratization of this digital transformation — where all participants in the supply chain have access to advanced digital technology — will be critical for manufacturing to survive and thrive, especially for small to midsize manufacturers (SMMs). This will be even more important in industries and states that produce parts for the internal combustion engine, such as Indiana. In essence, these companies need to transform both product and process simultaneously.

Smart manufacturing uses and integrates digital software tools and data throughout the product lifecycle. In a smart plant, every resource is digitalized. That means not only every operation, every cell (grouping of machines), and every line that is contributing to production, but also every forklift, all maintenance operations, inventory count on the line, and even the inventory that is still on the road and will arrive at the plant in a few hours is digitally tracked and optimized.

In a smart manufacturing plant, we always have perfect visibility into the current state of the plant (are we ahead of plan or behind, what machines are up or down, etc.). We have AI tools that will allow us to predict when things will deviate from the optimal stage. We have decision support systems that will guide us to make the best possible decision for the six key performance indicators (KPIs) — throughput, quality, cost, on-time delivery, sustainability, and (the latest addition) resiliency. These KPIs are interdependent, so it is crucial that all data and tools are integrated, enabling us to see the impact of any decision on all six KPIs simultaneously.

Smart manufacturing consists of five connected major elements:

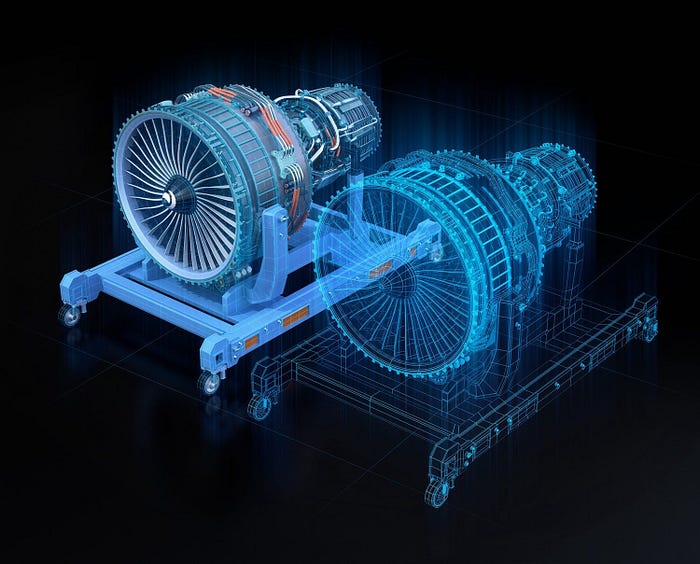

- Virtual manufacturing. We take a digital representation of a product (a “product digital twin”) as input and simulate its launch in a virtual factory to optimize manufacturing processes and systems (“process digital twin”), so we can find and solve problems beforehand in both product performance and process.

- Optimization of factories and supply chains in real time on the factory floor. We feed plant-floor data into process digital twins roughly every second, from controls, robots, sensors, cameras, and IT systems — or even from technicians, supervisors, or plant managers — and then use AI and analytics to optimize the factory’s KPIs.

- Predictive maintenance. When customers are using the product, sensors on the product predict when it will have to be maintained and what maintenance will have to be performed. Sensor data and decision support software helps direct the product into the most appropriate service shop. You might have seen this when your car continuously tells you its remaining oil life, which is based on sensoric and driving data.

- Real-time optimized service shops. In the service shops, we optimize for throughput, quality, cost, and on-time delivery, again modifying the digital twin of the real product.

- Digital thread. Smart manufacturing requires seamless data connectivity — a “digital thread” from virtual manufacturing through factory and supply chain, to usage, to service shop, back to product design “closing the loop.” We analyze data and optimize all along this digital thread to continuously improve product and manufacturing.

We are still in the early stages of the smart manufacturing revolution, and hurdles remain. Some 98 percent of all manufacturers are SMMs, with fewer than 500 employees. A lot of them don’t have the people and resources to implement smart manufacturing. And even if they solve the resource problem, they often still don’t know where to start. We talk a lot about resilient supply chains these days, especially after the COVID-19 pandemic. But resilient supply chains require digitalization and transparency for the entire supply chain — not just for the large manufacturers.

We are planning three major initiatives at Purdue to advance smart manufacturing:

- We will build a demonstration of a complete smart manufacturing loop, including tools for real-time factory and supply optimization.

- We will help create the manufacturing research and innovation ecosystem for SMMs, engage with students and the National Institute of Standards and Technology (NIST) Manufacturing Extension Partnership in pilot implementations, and explore new not-for-profit business models to scale innovations for SMMs (and large manufacturers).

- And we will create groundbreaking educational offerings in the Purdue School of Business to make it the best business school for digital-industrial technology on the planet.

On a personal note, I worked at General Motors when we went through bankruptcy and it was not clear if the U.S. auto industry would survive. The industry’s demise would have meant that most of Michigan (and maybe Ohio and Indiana) would have been deindustrialized. I had a newborn and a 4-year-old at the time, and I was worried for their future. I still vividly remember the depressed mood of the community, where nobody smiled anymore. I understand and empathize with communities where manufacturing has disappeared, and understand the societal impact on those communities.

Smart manufacturing can help keep existing manufacturing in the U.S. and contribute to reshoring efforts. The key innovation is the seamless integration of digital tools to create the smart manufacturing loop in order to continuously improve product and manufacturing throughout the entire value chain, making it more profitable, more sustainable, and more resilient — hitting the refresh button on the American dream.